Machines

Individual Design

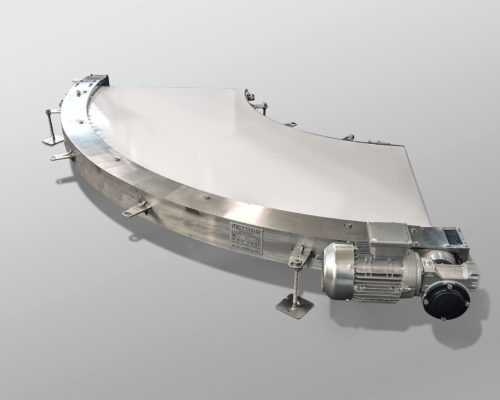

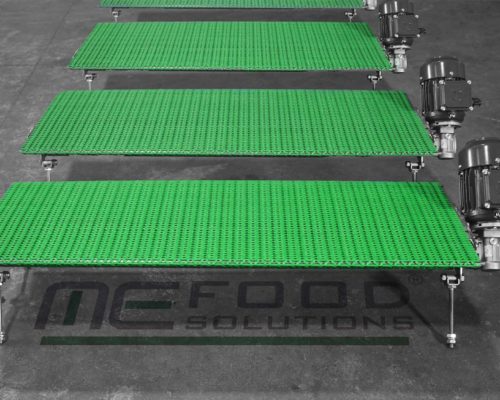

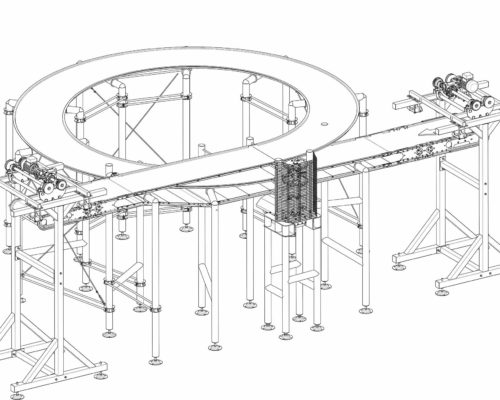

Washing and drying system for belt DLW

The Washing and Drying system for belt DLW was developed by ME Food Solutions to meet the high standards of the market and to implement the company’s philosophy of hygiene.

Cleaning systems applied to all equipment on the basis of conveyor belt DLSNS are capable to ensure full compliance with hygienic standards of food production.

The system consists of three elements: a washing unit, a drying unit and a control unit.

A detergent dosing unit before washing and disinfectant after washing is available as an optional.

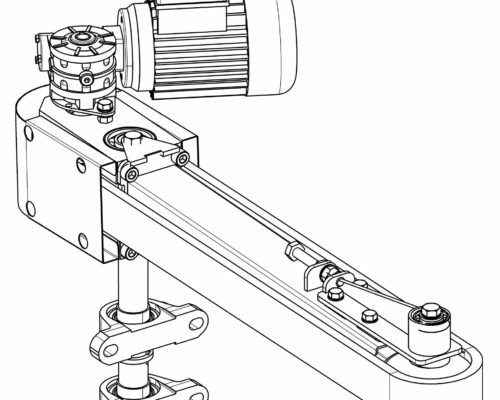

Washing unit

The washing unit consists of a container with a stainless steel cap AISI 304, which allows to hold and remove the washing liquid.

Rotary nozzles are mounted inside the container and wash the belt with high pressure water. The number of nozzles depends on the width of the belt used.

The waste water flows into the lower part of the reservoir and is diverted outwards through the drain pipe.

Drying unit

The drying unit consists of a container with a stainless steel lid AISI 304 which allows to hold and remove water residues during the drying process. The air pumped by the turboprop enters in 2 aerial knives mounted transversally from above and below.

The narrow cross-section of the openings of the air knives makes it possible to achieve a high air speed at the outlet and to reliably remove moisture from the conveyor belt. The remaining water flows into the lower part of the reservoir and is discharged outwards through a drain pipe.

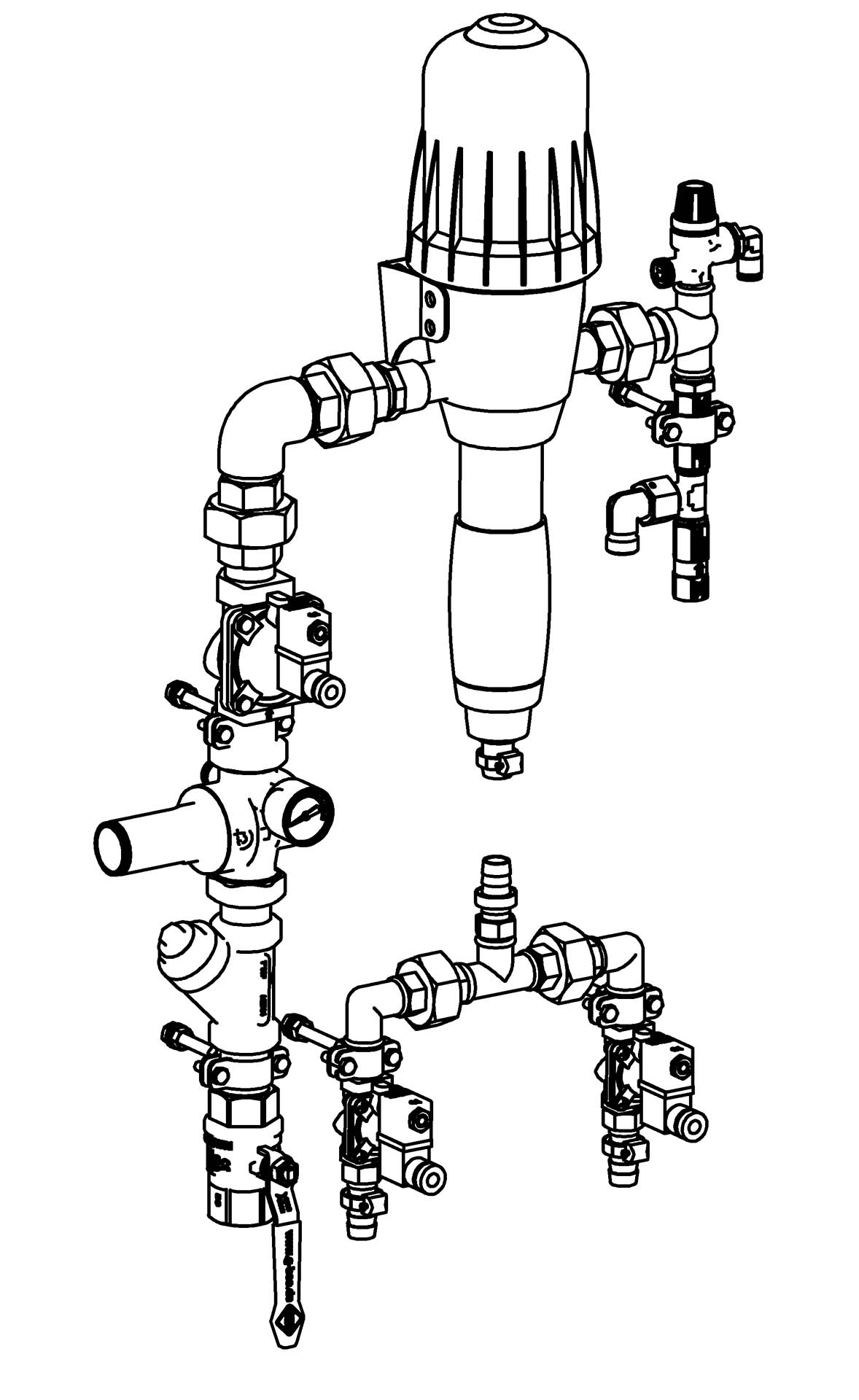

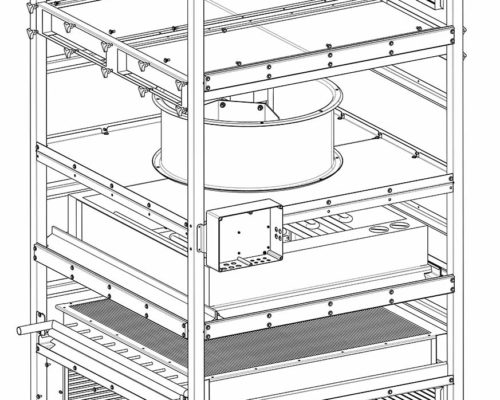

Control unit

The control unit is a metal frame in the upper part of which a high-pressure pump is mounted for supplying water to the washing unit. The water flow can be up to 2,000 litres/hh. A turbofan is installed in the lower part of the frame to supply air to the washing unit. Both installations are the result of fruitful collaboration with leading companies in their sector

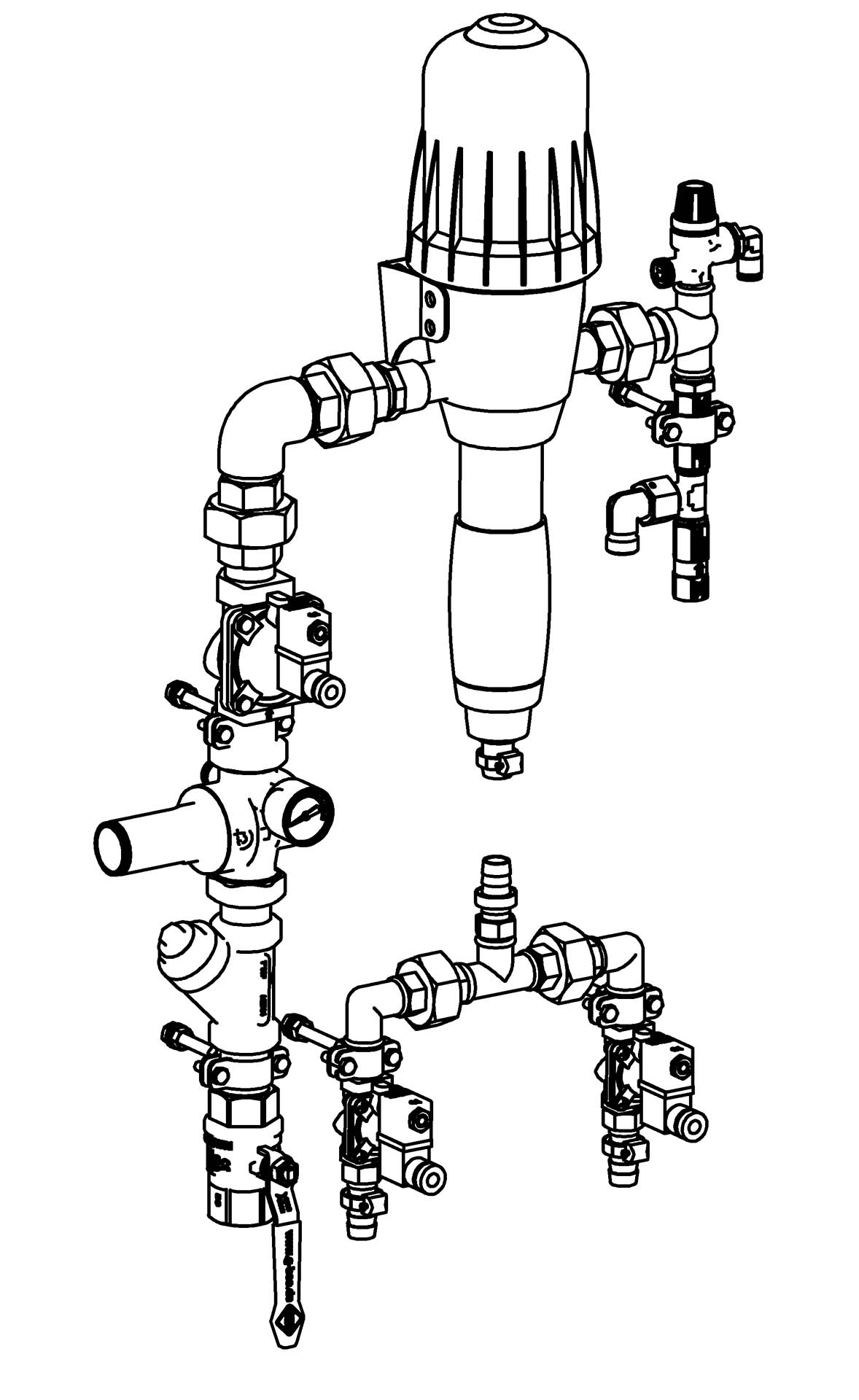

Detergent dosing unit

The automatic mixer connects to the water line and uses water pressure as the sole force to absorb the concentrated washing agent. The mixer also doses the detergent to a specified percentage ratio. This ratio remains constant even when the pressure and the water flow change.