Machines

Individual Design

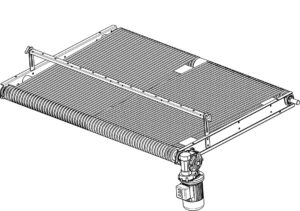

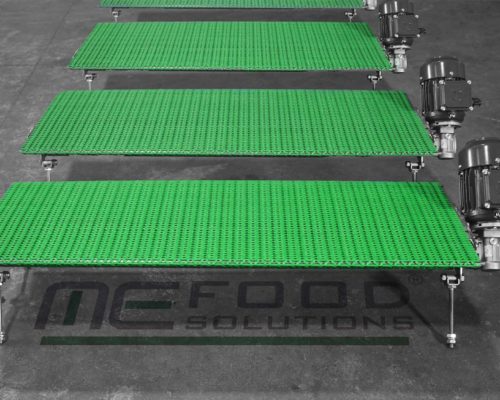

Food conveyor machine DLC

The DLC conveyor is a machine consisting of a frame support structure made of steel AISI304 on which flows a special chain of conveyor belts such as DLSNS belt. It’s patented by ME Food Solutions. The sliding surfaces are covered with profiles made with the latest generation of techno-polymer which provide slide without tension and with reduced friction.

ME Food Solutions pipelines can be made in any configuration requested by the customer. They can be attached to the floor or suspended from the ceiling without any length restriction. They are designed for linear or curved tracks, flat or steep. Movement is generated by the drive engine mounted on one side of the conveyor by the horizontal rotation of the gear shaft.

Depending on the type of product loaded, the edges and side fins may have different heights. All parts are made of stainless steel AISI304, technical polymer are FDA certified.

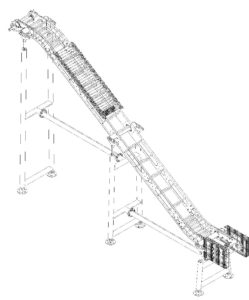

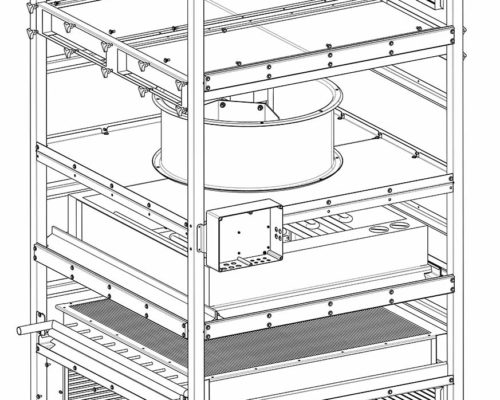

Conveyor DLC LIFTER

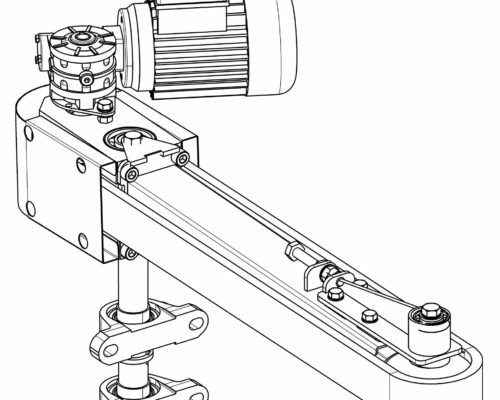

ME Food Solutions Lifter Conveyor is the only available example of a mobile conveyor with a torsion tyre system. This system is based on a pneumatic piston (with a solenoid valve) located at the base. This piston raises the plane of the conveyor belt with adjustable inclination. Movement is effected by the use of a torque rod with a gear system.

This operation is always controlled by the HMI interface. This control allows the product to be transmitted in alternating phases along different lines. Belt configurations remain unchanged in relation to the DLC pipeline. The mesh is made of stainless steel AISI 304 or engineering plastic. This safe and innovative solution provides more flexibility in designing complex transport systems.

Conveyor DLC LIFTER

Lifter ME Food Solutions is the only available example of a mobile conveyor with a torsion tyre system. This system is based on a pneumatic piston (with a solenoid valve) located in the base. This piston raises the plane of the conveyor belt with adjustable inclination. Movement is effected by the use of a torque rod with a gear system.

This operation is always controlled by the HMI interface. This control allows the product to be transmitted in alternating phases along different lines. Belt configurations remain unchanged in relation to the DLC pipeline. The netted base is made of stainless steel AISI 304 or engineering plastic. This safe and innovative solution provides more flexibility in designing complex transport systems.

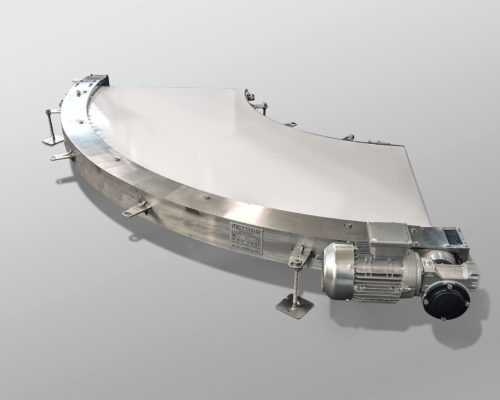

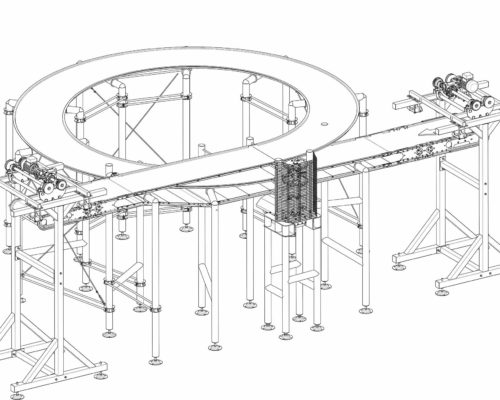

Other types of Conveyors

Flexibility has always been part of the basic philosophy of ME food solutions. A concrete example is the range of pipelines developed and manufactured, as well as the wide range of applications.

Thus, the main and most popular species are: conveyor with scrapers, conveyor with modular belt, cord belt conveyor and free rollers conveyor.

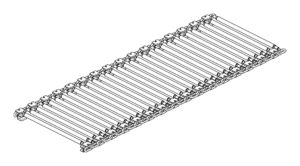

The conveyor with modular belt is specially designed and applied in specific cases when DLSNS belt cannot be used. The conveyor belt is driven by an engine-reducing gear mounted on one of the conveyor ends. The motor reducer rotates a transverse shaft with toothed wheels which enter into engagement with the tape and drive it in motion.

This type of conveyor is equipped with scrapers (blades) to hold the product on the tape when climbing upwards. The scrapers are mounted on lateral sliding profiles, across the tape and parallel to each other. The scrapers keep the product from slipping down while the belt moves.

The conveyor with modular belt is specially designed and applied in specific

cases when DLSNS belt cannot be used. The conveyor belt is driven by an engine-reducing gear mounted on one of the conveyor ends. The motor reducer rotates a transverse shaft with toothed wheels which enter into engagement with the tape and drive it in motion.

The wide range of conveyor lines is the result of the ME Food Solution’s experience which was obtained through the implementation of a large number of projects.