Machines

Individual Design

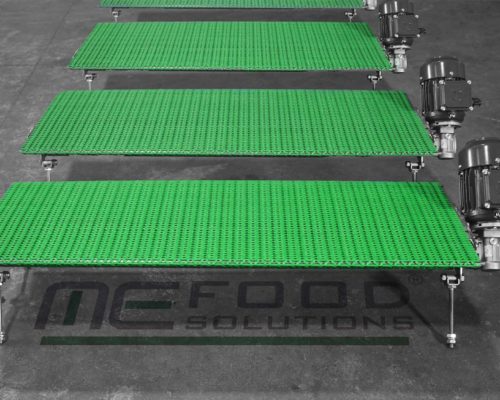

Conveyor belt for food products that does not require lubricant

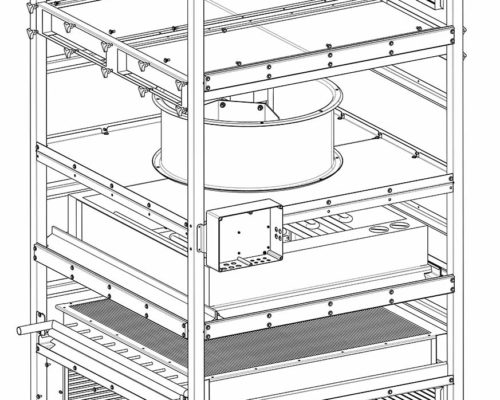

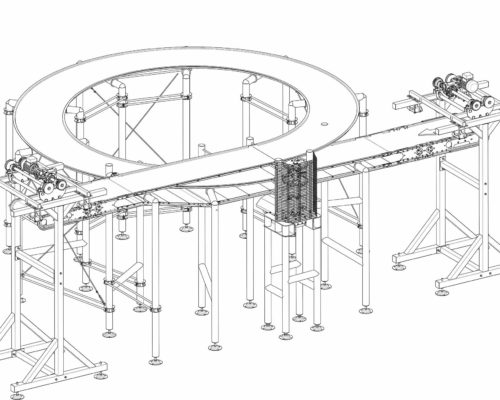

Coiled conveyor systems are an integral part of modern food production, which plays a key role in automation and optimization of production processes. They can be used to organize various types of food processing such as freezing, cooling, proofing, pasteurization, transportation. ME Food Solutions offers not only spirals but also complex solutions for the organization of the entire production line.

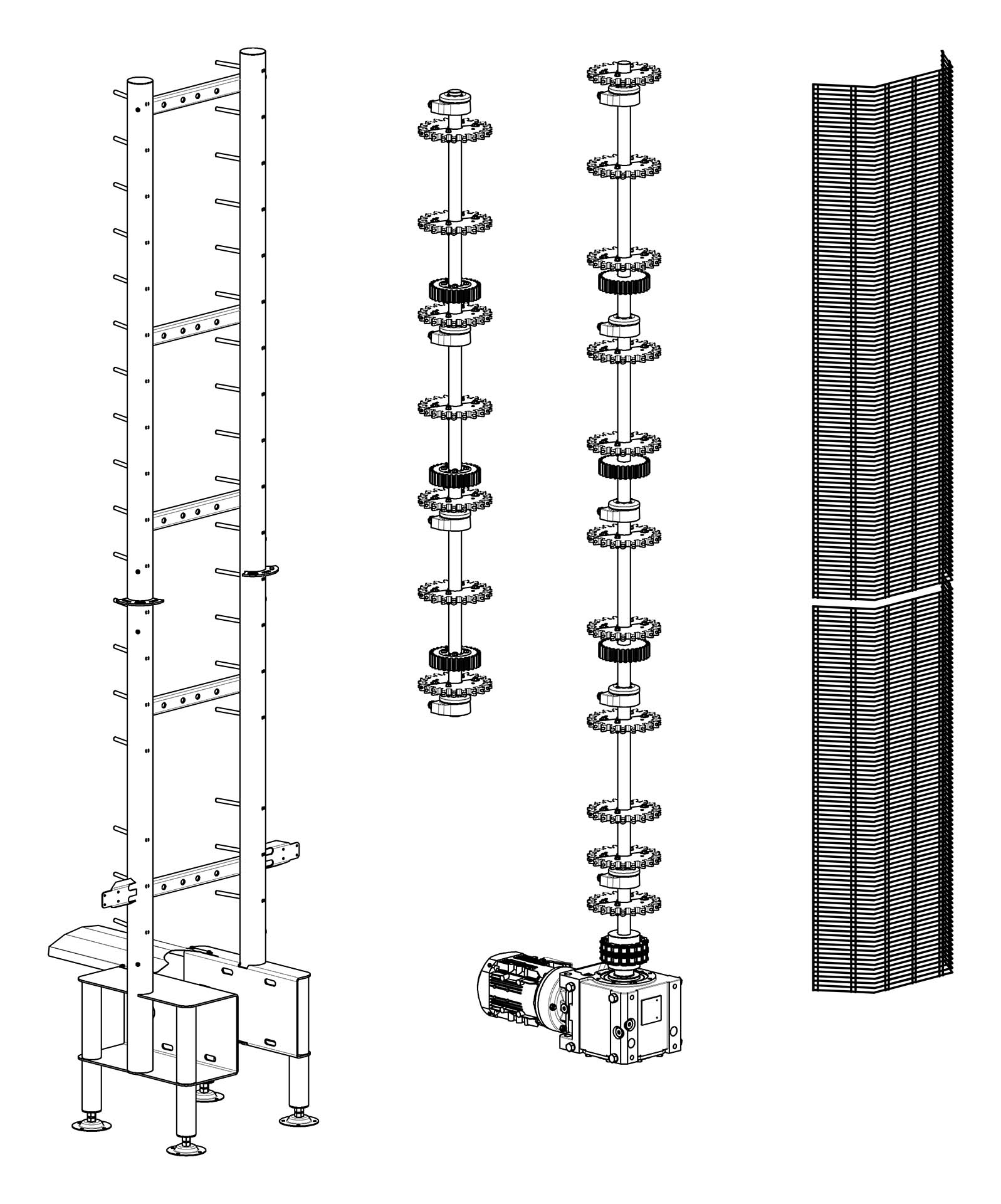

ME Food Solutions spiral conveyors based on DLSNS belt can have an unlimited number of configuration variants. According to the specifications of the customer, shape and size of the spiral, width and length of the conveyor belt, position of loading and unloading of the spiral conveyor are chosen. It is a frame of circular stainless steel pipes AISI 304 with guides for moving the conveyor belt. Using low-friction components, the belt moves smoothly and does not require lubrication.

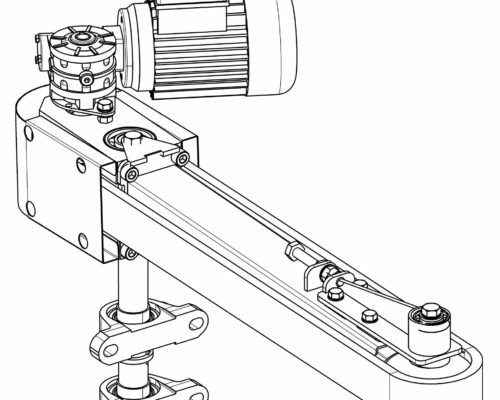

The wheels mounted for vertical towing are activated by the gears and transmit movement to the entire helix DLS-EVO.

For complex spirals, multiple vertical thrusts can be synchronized and connected by corner gearboxes or mechanical transmissions to a horizontal tow. The speed is variable and can always be controlled on the electrical panel via HMI interface.

Food machine DLS–EVO: infinite flexibility

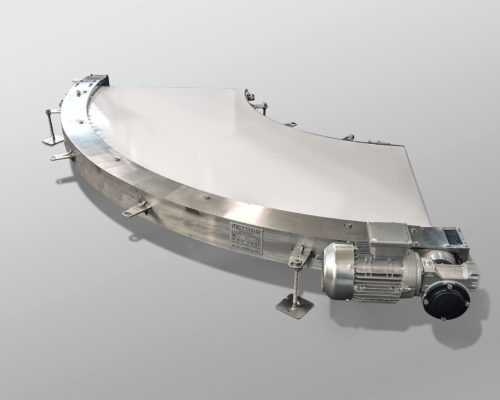

The DLSNS-EVO spiral is a high-performance food machine that is unlimited in configuration capabilities. It has no restrictions in form. Moreover, loading and unloading can be located anywhere.

Conveyor direction can be clockwise or counterclockwise. Also up to 4 conveyor belts can slide simultaneously.

Belts have no limit in length, variable distance between the planes and maximum space optimization. In non-standard cases, ME Food Solutions secured spirals around pillars.